Product Description

Air Compressor Gear for Atlas Copco

Product Description

More Air Compressor Gear for Altas Copco

10920127

1092

1614933

16212405

16212411

16212417

16212424

16212426

16138981

16138537

16138444

16138672

225710841

16165635

16233961

16165639

16233983

22571 0571

16233265

16233992

1291

16233936

16165682

16165633

16149329

16139656

16166424

16049107

16165629

16165396

12571156

16165559

16149328

1657161

12571264

2906059

16042508

13257116

22529043

16165567

16149682

12571275

16165705

22525762

16231067

16166418

16165652

16219062

16138557

16156393

12026765

16215713

12026762

16212425

16139639

12026763

16138979

16149313

16149345

16149675

16212422

161662571

16139657

16155392

162257171

22538256

162257171

16165433

2254115

16234059

12026769

22527476

161662571

29060569

12571149

13257110

16138774

16231108

16165552

22521794

2253763

22529229

16164444

12571272

12571966

1621432

1622571

16149312

2906571

16040545

16149676

1622

16165514

22529044

16231096

16233931

1657114

16149679

16139642

16139643

225415710

16139634

16149337

1616574

12571273

1657163

16139635

12571598

16165653

2254115

1621243

22529045

16165631

16149672

16139647

16149671

1622

1606128

22541

22355786

16149677

16138446

16138865

225718067

16165566

16139644

22525763

16214882

16212118

16138359

16155391

12026729

29065718

1612517

16149335

16149327

16149315

162205710

16233967

2254571

2254571

1616563

165711

16212442

2254571

22541719

16165409

1622

16139645

291

22537632

21571769

16166421

16214138

22528947

1616564

2252923

16132761

12026764

1257115

16149684

12571962

1614933

1657117

16166422

1616556

16149304

16231 0571 0

16149336

1616576

16149334

161493

162257171

2157177

12571263

29060658

16138163

16138775

16165554

1621244

16165399

2254571

2254571

12571599

16165651

16149326

16219278

12571185

21571751

12026016

16149307

22527473

16215715

16212421

1616571

161662 0571

22521793

16212418

165711101

161662 0571

29065712

16138773

12571271

12571184

162155714

12571963

16165555

10921088

10921068

1092

1092

1092

1092

1092

1092

1092

1092571

10921067

10921048

10921098

109215710

109215710

10921069

1092

1092

1092

1092

1092

1092

1092

16212428

16212433

162315710

1623108

1625

165711180

1625

1625

1625

1625

1625

1625

1625

1625

1625

162657180

1625

1625

22541

1625

1625

162557105

1625

1625

1625

1625

1625

1625

1625

1625

1625

1625

1625

1625

1625

1625

pack your goods?

There is 3 kinds of ways to packed the goods, which depends on your requirement

1. Packed with original package

2. Packed with your design package

3. Packed with our blank package, below is the example for referenc

Air Compressor Gear for Altas Copco FAQ

Q1: How can I get the quotation?

A: you can advise us the part number for checking, and we will quote to you soon by email

Q2: What kind of ways for transportation ?

A:In general by air, sea or Express.(like DHL,Fedex,TNT,etc.)

Q3: How do I know the quality of productions?

A:We have a strict series of quality control, and we have perfect after service system, which can help you to solve the problem soon

Q4: If i want to change model,size,package,etc. How can I do?

A:You can contact us by or mail, and we will revise according to your requirement

Q5: What is the terms of payment ?

A: T/T, Western Union, paypal

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Lubrication Style: | Oil-free |

|---|---|

| Cooling System: | Air Cooling |

| Power Source: | AC Power |

| Cylinder Position: | Vertical |

| Structure Type: | Closed Type |

| Installation Type: | Stationary Type |

| Customization: |

Available

| Customized Request |

|---|

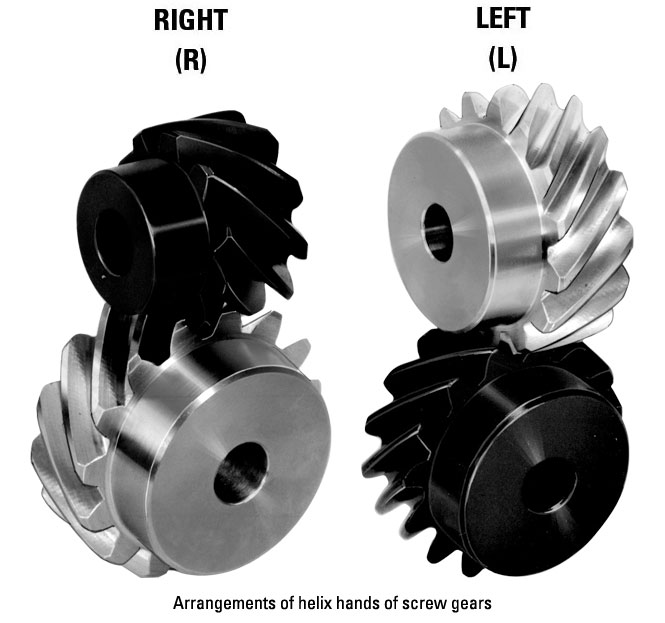

Are screw gears suitable for high-torque applications?

Using screw gears, also known as worm gears, in high-torque applications requires careful consideration. The torque capacity of screw gears can be a limiting factor due to their unique design and characteristics. Here’s a detailed explanation of the suitability of screw gears for high-torque applications:

Yes, screw gears can be suitable for high-torque applications, but there are certain limitations to consider:

- Lower Torque Capacity: Screw gears generally have a lower torque capacity compared to other gear types, such as spur gears or helical gears. The sliding contact between the worm gear and worm wheel, coupled with the high gear ratios typically associated with screw gears, can result in higher contact stresses and increased wear. Therefore, screw gears are generally not the first choice for applications with extremely high torque requirements.

- Efficiency and Heat Generation: In high-torque applications, the efficiency of the gear system becomes crucial. Screw gears, due to their sliding motion and higher friction compared to other gear types, can have lower mechanical efficiency. This lower efficiency leads to increased heat generation, which may be a concern in high-torque applications where heat dissipation becomes challenging. Proper lubrication, cooling, and heat management strategies are important to ensure reliable operation under high torque conditions.

- Load Distribution: The load distribution in a screw gear mechanism is not as uniform as in some other gear types. The load is concentrated on a limited number of teeth, which can lead to higher tooth stresses and potential wear. This concentration of load can be a limiting factor in high-torque applications, as it can result in premature gear failure or reduced lifespan.

- Application-Specific Considerations: While screw gears may have limitations in high-torque applications, there are scenarios where they can still be suitable. For example, in applications that require precise positioning, heavy loads, or the ability to hold position without additional braking mechanisms, the self-locking feature of screw gears can be advantageous. Additionally, advancements in gear design, materials, and lubrication can help improve the torque capacity and performance of screw gears in specific high-torque applications.

When considering the use of screw gears in high-torque applications, it is important to carefully evaluate the specific torque requirements, operating conditions, and other factors such as speed, duty cycle, and environmental considerations. Consulting with experienced engineers and conducting thorough analysis will help determine whether screw gears are suitable or if alternative gear types should be considered to meet the high-torque demands of the application.

How do you address thermal expansion and contraction in a screw gear system?

Addressing thermal expansion and contraction in a screw gear system is crucial to ensure the proper functioning and longevity of the system. Thermal expansion and contraction occur when a system is subjected to temperature changes, leading to dimensional changes in the components. Here’s a detailed explanation of how to address thermal expansion and contraction in a screw gear system:

- Material Selection: Choose materials for the screw gear system components that have compatible coefficients of thermal expansion (CTE). Using materials with similar CTE can help minimize the differential expansion and contraction between the components, reducing the potential for misalignment or excessive stress. Consider materials such as steel, bronze, or other alloys that exhibit good dimensional stability over the expected operating temperature range.

- Design for Clearance: Incorporate proper clearances and tolerances in the design of the screw gear system to accommodate thermal expansion and contraction. Allow for sufficient clearance between mating components to accommodate the expected dimensional changes due to temperature variations. This can prevent binding, excessive friction, or damage to the gears during temperature fluctuations.

- Lubrication: Utilize appropriate lubrication in the screw gear system to mitigate the effects of thermal expansion and contraction. Lubricants can help reduce friction, dissipate heat, and provide a protective film between the mating surfaces. Select lubricants that offer good thermal stability and maintain their properties across the expected temperature range of the system.

- Thermal Insulation: Implement thermal insulation measures to minimize the exposure of the screw gear system to rapid temperature changes. Insulating the system from external heat sources or environmental temperature fluctuations can help reduce the thermal stresses and minimize the effects of expansion and contraction. Consider using insulating materials or enclosures to create a more stable temperature environment around the screw gear system.

- Temperature Compensation Mechanisms: In certain applications, it may be necessary to incorporate temperature compensation mechanisms into the screw gear system. These mechanisms can actively or passively adjust the position or clearance between components to compensate for thermal expansion or contraction. Examples include thermal expansion compensation screws, bimetallic elements, or other devices that can accommodate dimensional changes and maintain proper alignment under varying temperatures.

- Operational Considerations: Take into account the thermal characteristics of the environment and the operational conditions when using a screw gear system. If the system is expected to experience significant temperature variations, ensure that the operating parameters, such as load capacities and operating speeds, are within the design limits of the system under the anticipated temperature range. Monitor and control the temperature of the system if necessary to minimize the effects of thermal expansion and contraction.

- System Testing and Analysis: Conduct thorough testing and analysis of the screw gear system under various temperature conditions to assess its performance and behavior. This can involve measuring dimensional changes, analyzing gear meshing characteristics, and evaluating the system’s ability to maintain proper alignment and functionality. Use the test results to validate the design, make any necessary adjustments, and optimize the system’s performance under thermal expansion and contraction effects.

- Maintenance and Inspection: Establish a regular maintenance and inspection routine for the screw gear system to monitor its performance and address any issues related to thermal expansion and contraction. This can involve checking clearances, lubrication levels, and the overall condition of the system. Promptly address any signs of excessive wear, misalignment, or abnormal operation that may be attributed to temperature-related effects.

By considering material selection, design clearances, lubrication, thermal insulation, temperature compensation mechanisms, operational considerations, and regular maintenance, it is possible to effectively address thermal expansion and contraction in a screw gear system. These measures help ensure the system’s reliability, minimize wear and damage, and maintain the desired performance and functionality over a range of operating temperatures.

How do you choose the right size screw gear for your application?

Choosing the right size screw gear for your application involves considering several factors to ensure optimal performance and compatibility. Here are the key steps to follow when selecting a screw gear:

- Determine the Application Requirements: Start by understanding the specific requirements of your application. Consider factors such as the desired gear reduction ratio, torque requirements, rotational speed, load capacity, and precision positioning needs. Having a clear understanding of your application’s requirements will help guide the selection process.

- Calculate the Gear Ratio: Determine the required gear reduction ratio by considering the speed and torque specifications of your application. The gear reduction ratio is calculated by dividing the input speed by the output speed. This ratio will help narrow down the options for suitable screw gears.

- Evaluate Load Capacity: Assess the load capacity requirements of your application. Consider the maximum load that the screw gear needs to handle. This includes both the static load (the load when the system is at rest) and the dynamic load (the load during operation). Ensure that the selected screw gear can handle the anticipated loads without experiencing excessive wear or failure.

- Consider Torque Requirements: Determine the required torque output of the screw gear to meet the demands of your application. Calculate the torque by multiplying the load torque by the gear reduction ratio. Ensure that the selected screw gear can provide the necessary torque output to drive the load effectively.

- Analyze Speed and Efficiency: Evaluate the desired rotational speed and efficiency of the screw gear system. Consider the input speed, output speed, and efficiency requirements of your application. Ensure that the selected screw gear can operate within the desired speed range while maintaining the required efficiency levels.

- Check Mounting and Space Constraints: Assess the available space and mounting requirements in your application. Consider factors such as the required size, shape, and mounting configuration of the screw gear. Ensure that the selected screw gear can be properly installed and integrated into your application without any space or mounting constraints.

- Consider Material and Lubrication: Evaluate the environmental conditions and operating parameters of your application. Consider factors such as temperature, humidity, exposure to contaminants, and the need for corrosion resistance. Select a screw gear made from materials suitable for the application environment. Additionally, consider the lubrication requirements and ensure that the selected screw gear can be adequately lubricated for smooth operation and reduced wear.

- Consult Manufacturers and Suppliers: Seek advice and consult with manufacturers or suppliers of screw gears. They can provide valuable insights and recommendations based on their expertise and product knowledge. Provide them with the specific details of your application requirements for better guidance in selecting the appropriate screw gear.

By following these steps and considering the factors mentioned, you can choose the right size screw gear that matches the requirements of your application. It is crucial to ensure that the selected screw gear can handle the load, provide the necessary torque and speed, fit within the available space, and operate effectively in the application environment.

editor by Dream 2024-04-22