Product Description

| 1 |

One type of gear commonly used in air compressors is the helical gear. Helical gears have angled teeth that gradually engage with each other, resulting in smooth and quiet operation. They are often used in the compressor pump to drive the crankshaft and compress air.

Another type of gear used in air compressors is the spur gear. Spur gears have straight teeth that engage with each other, resulting in a more efficient transfer of power but also a louder operation. They are often used in the compressor motor to transfer power to the pump.

The term “bulk gear” could potentially refer to a gear that is used in large quantities or purchased in bulk for use in multiple air compressors. However, without more context or information, it is difficult to provide a more specific answer.

| After-sales Service: | Online Service |

|---|---|

| Warranty: | One Year |

| Lubrication Style: | Oil-free |

| Cooling System: | Water Cooling |

| Power Source: | AC Power |

| Cylinder Position: | Horizontal |

| Customization: |

Available

| Customized Request |

|---|

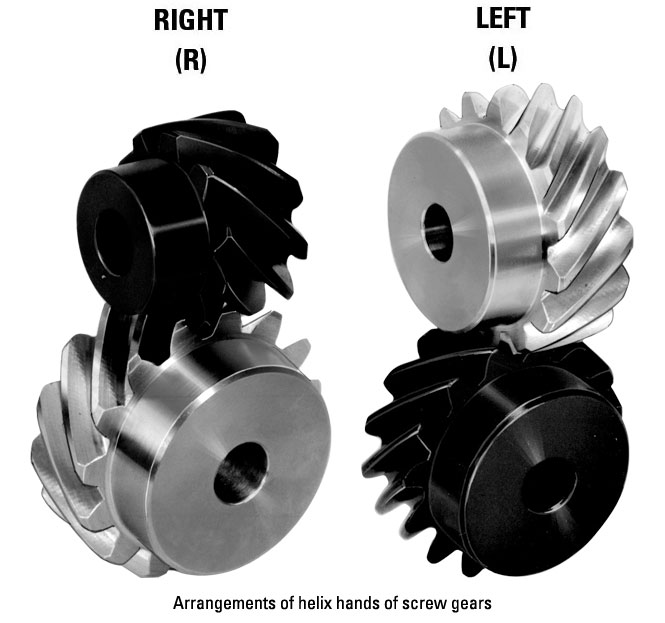

What is the purpose of using screw gears in machinery?

Screw gears, also known as worm gears, serve various purposes in machinery and mechanical systems. They offer unique advantages that make them suitable for specific applications. Here’s a detailed explanation of the purposes and benefits of using screw gears:

- High Gear Reduction: One of the primary purposes of using screw gears is to achieve high gear reduction. Screw gears provide a significant reduction ratio, allowing for the conversion of high-speed, low-torque input to low-speed, high-torque output. This makes them ideal for applications that require precise control over torque and rotational speed, such as lifting heavy loads, positioning systems, and machinery with high torque requirements.

- Precise Positioning: Screw gears enable precise positioning and control of linear or rotary motion. The fine-pitch threads on the worm and the corresponding worm wheel teeth allow for accurate and controlled motion. This feature makes screw gears suitable for applications that require precise positioning, such as robotics, automation, and machinery that performs intricate movements or adjustments.

- Self-Locking: Screw gears have a self-locking property, which means that the gear mechanism remains fixed in position even when no external force is applied. The friction between the screw threads and the worm wheel prevents the system from backdriving or rotating unintentionally. This self-locking feature eliminates the need for additional braking mechanisms or external locks, making screw gears advantageous in applications where holding a position is essential for safety and stability.

- Compact Design: Screw gears have a compact design that makes them suitable for applications with limited space. The worm and worm wheel arrangement allows for efficient power transmission in a compact layout, enabling the integration of screw gears in machinery and systems where space is a constraint. This compact design also simplifies installation and reduces the overall footprint of the equipment.

- Quiet and Smooth Operation: Screw gears operate with reduced noise and vibration compared to other gear types. The helical nature of the threads and the sliding/rolling contact between the worm and worm wheel result in a smooth and gradual meshing motion. This smooth operation contributes to quieter machinery, making screw gears desirable in applications where noise reduction is important, such as in residential environments, audio equipment, and precision instruments.

- High Shock Load Resistance: Screw gears are known for their ability to handle shock loads effectively. The helical shape of the threads and the larger contact area between the worm and the worm wheel distribute the load more evenly, reducing the risk of sudden failures or damage due to shock or impact loads. This shock load resistance makes screw gears suitable for applications that involve sudden changes in load or external forces.

- Reliability and Durability: Screw gears are recognized for their reliability and durability. The simplicity of their design, with fewer moving parts, reduces the likelihood of mechanical failures. Additionally, the self-locking feature minimizes the chances of unwanted movement or slippage. When properly lubricated and maintained, screw gears can have a long service life and require minimal maintenance, contributing to the overall reliability of machinery.

- Wide Range of Applications: Screw gears find application in various industries and machinery types. They are utilized in manufacturing equipment, robotics, medical devices, automotive systems, elevators, material handling machinery, and many other systems that require precise control, high torque, compactness, and reliable power transmission.

The purpose of using screw gears in machinery is to provide efficient power transmission, precise positioning, high torque multiplication, self-locking capabilities, and reliable operation. These features make screw gears a valuable component in numerous applications, enhancing performance, safety, and overall functionality of machinery and mechanical systems.

Can screw gears be used in heavy-duty machinery and equipment?

Yes, screw gears, also known as worm gears, can be used in heavy-duty machinery and equipment. Screw gears offer several advantages that make them suitable for such applications. Here’s a detailed explanation of using screw gears in heavy-duty machinery and equipment:

- High Load Capacity: Screw gears are known for their high load-carrying capacity. The helical design of the gear teeth allows for distributed contact between the worm gear and the worm wheel, enabling them to handle significant loads. This makes screw gears well-suited for heavy-duty applications where large forces and torque need to be transmitted.

- Self-Locking Capability: Screw gears have a self-locking feature, which means they can hold position without the need for additional braking mechanisms. In heavy-duty machinery and equipment, this self-locking capability can be advantageous, especially when it is necessary to prevent the load from moving or to maintain position under static or dynamic loads.

- Compact Design: Screw gears have a compact design, which allows for space-saving installations in heavy-duty machinery and equipment. Their axial orientation and the ability to achieve high gear ratios in a single stage contribute to their compactness. This is particularly beneficial in applications where space is limited or where a compact gear system is desirable.

- Smooth and Quiet Operation: Screw gears generally operate with low noise and vibration levels. The helical nature of the gear teeth engagement results in smooth and continuous contact, reducing noise and minimizing vibrations. This is advantageous in heavy-duty machinery and equipment, where quiet operation is often desired to enhance operator comfort and minimize the impact on surrounding components.

- High Gear Reduction Ratios: Screw gears can achieve high gear reduction ratios in a single stage, which is beneficial in heavy-duty applications that require significant speed reduction or torque multiplication. This eliminates the need for multiple gear stages or additional components, simplifying the gear system design and reducing the overall complexity.

- Durability and Longevity: Screw gears are known for their durability and long service life. When properly designed, manufactured, and maintained, they can withstand heavy loads, operate under challenging conditions, and exhibit good resistance to wear and fatigue. This makes them suitable for heavy-duty machinery and equipment that operate in demanding environments.

- Compatibility with Various Materials: Screw gears can be manufactured from different materials to suit specific application requirements. This flexibility allows for compatibility with various other components and materials used in heavy-duty machinery and equipment. The choice of materials can be tailored to factors such as strength, wear resistance, and compatibility with lubricants or operating conditions.

In summary, screw gears can be effectively used in heavy-duty machinery and equipment due to their high load capacity, self-locking capability, compact design, smooth operation, high gear reduction ratios, durability, and compatibility with different materials. By considering the specific requirements of the application and employing proper design and manufacturing practices, screw gears can provide reliable and efficient power transmission in heavy-duty scenarios.

Can you explain the concept of screw gear threads and their functions?

Screw gear threads play a crucial role in the operation and functionality of screw gears, also known as worm gears. The threads are an essential component of the worm, which is the cylindrical gear with a helical thread wrapped around it. Here is a detailed explanation of the concept of screw gear threads and their functions:

- Thread Design: The threads on a screw gear, specifically the helical thread on the worm, are designed in a helical shape, resembling the threads of a screw. The helical thread is wrapped around the cylindrical body of the worm, creating a continuous spiral path along its length. The pitch of the thread refers to the distance between successive thread crests or valleys.

- Meshing with Worm Wheel: The primary function of the screw gear threads is to mesh with the teeth of the worm wheel. The helical thread of the worm engages with the teeth of the worm wheel, creating a sliding contact between them. As the worm rotates, the helical thread drives the rotation of the worm wheel, transmitting rotational motion and power.

- Gear Reduction and Torque Multiplication: The helical design of the screw gear threads allows for a large number of teeth on the worm wheel to be engaged at any given time. This results in a high gear reduction ratio, meaning that for each revolution of the worm, the worm wheel rotates by a smaller fraction. The gear reduction ratio enables torque multiplication, making screw gears suitable for applications requiring high torque output.

- Precision Positioning: Screw gear threads are crucial for achieving precise positioning in applications where accuracy is essential. The fine pitch of the helical thread allows for small incremental movements, enabling precise control over the rotation of the worm wheel. This feature is particularly advantageous in applications such as robotics, where accurate positioning and motion control are necessary.

- Self-Locking Action: The helical thread design of screw gears gives them a self-locking capability. When the worm is not rotating, the friction between the helical thread and the teeth of the worm wheel tends to hold the gear system in place. This self-locking action prevents the worm wheel from backdriving the worm, providing inherent braking or locking functionality. It ensures that the gear mechanism maintains its position without the need for additional braking or locking mechanisms.

- Efficiency and Lubrication: The sliding action between the screw gear threads and the teeth of the worm wheel introduces more friction compared to other types of gears with rolling motion. This sliding motion affects the efficiency of the gear mechanism, resulting in higher energy losses and heat generation. Proper lubrication with appropriate lubricants is essential to minimize wear, reduce friction, and improve the overall efficiency of the screw gears.

Overall, screw gear threads enable the meshing and transmission of rotational motion and power between the worm and the worm wheel. They facilitate gear reduction, torque multiplication, precise positioning, and self-locking action. Understanding the design and functions of screw gear threads is crucial for utilizing screw gears effectively in various applications.

editor by CX 2023-11-02