Product Description

1.Chain used

sprocketes are manufactured with a tooth profile and dimensional precision to bring out the maximum performance of the chain you will use.

2. Number of teeth

sprockets are available with small and large numbers of teeth to match your usage conditions.

|

Single pitch sprocket |

Double pitch sprocket |

||||

|

*Chain matched:35(06C) /06BTeeth:from 9-120 *Chain matched:40(08A) /08BTeeth:from 9-120 *Chain matched:50(10A) /10BTeeth:from 9-120 *Chain matched:60(12A) /12BTeeth:from 9-120 *Chain matched:80(16A) /16B Teeth:from 9-120 *Chain matched:100(20A)/20B Teeth:from 9-120 *Chain matched:120(24A) /24B Teeth:from 9-120 *Chain matched:140(28A) /28B Teeth:from 9-120 *Chain matched:160(32A) /32B Teeth:from 9-120 *Chain matched:200(40A) /40B Teeth:from 9-120 |

*P=25.4mm Teeth:from 7-100

*P=31.8mm Teeth:from 7-100

*P=38.1mm Teeth:from 7-100

*P=50.8mm Teeth:from 7-100

*P=63.5mm Teeth:from 7-100 |

3. Consturction

4. Material

Carbon Steel, Stainless Steel,Aluminum, Nylon, POM, Copper, Brass,42CrMo,40Cr,A3 and so on.

5. Bore

Pilot bore, finished bore, taper bore, bearing hole and special bore

6. Treatment

Heat Treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on.

Surface Treatment: Zinc Plating, Chrome plated, Black oxide Treatment, Spray Paint, Mirror Finish, Sand-blasting and so on.

FAQ

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3D drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Electric Cars, Motorcycle, Machinery, Agricultural Machinery |

| Hardness: | Hardened Tooth Surface |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample free sample

|

|---|

| Customization: |

Available

| Customized Request |

|---|

What lubrication is required for screw gears?

Proper lubrication is essential for the efficient and reliable operation of screw gears, also known as worm gears. The lubrication requirements for screw gears depend on various factors, including the application, operating conditions, and the materials used in the gear system. Here’s a detailed explanation of the lubrication considerations for screw gears:

Selection of Lubricant:

When selecting a lubricant for screw gears, it is important to consider the following factors:

- Type of Lubricant: There are different types of lubricants available, such as oils, greases, and solid lubricants. The selection depends on factors such as operating speed, temperature range, load capacity, and environmental conditions. Consult the gear manufacturer’s recommendations or industry standards to determine the suitable lubricant type for the specific application.

- Viscosity: The lubricant viscosity should be chosen based on the operating conditions of the screw gear system. Higher viscosity lubricants are typically used for heavier loads or higher temperatures, while lower viscosity lubricants are suitable for lighter loads or lower temperatures. The viscosity should be within the range recommended by the gear manufacturer.

- Additives: Some lubricants contain additives that provide additional benefits, such as improved anti-wear properties, corrosion resistance, or extreme pressure protection. Consider the specific requirements of the screw gear system and choose a lubricant with suitable additives, if necessary.

Lubrication Guidelines:

Here are some general guidelines for lubricating screw gears:

- Initial Lubrication: Apply an appropriate amount of lubricant during the initial installation of the screw gear system. Ensure that all gear surfaces, including the worm and the worm wheel, are adequately coated with lubricant.

- Replenishment: Regularly monitor the lubricant level and condition of the screw gear system. Over time, lubricant may degrade, become contaminated, or lose its effectiveness. Follow the manufacturer’s recommendations for lubricant replenishment intervals and quantities. In some cases, lubricant replenishment may be necessary during routine maintenance.

- Proper Lubricant Distribution: Ensure that the lubricant is evenly distributed across the contacting surfaces of the screw gears. The lubricant should adequately cover the threads of the worm and the teeth of the worm wheel to reduce friction and wear. Proper lubricant distribution can be achieved through rotational movement of the gears or by applying the lubricant directly to the contact area.

- Prevent Excessive Lubrication: While proper lubrication is essential, excessive lubrication can lead to problems such as overheating, increased drag, and leakage. Follow the manufacturer’s recommendations regarding the appropriate lubricant quantity. Avoid over-greasing or over-oiling the screw gear system.

- Cleanliness: Maintain cleanliness when lubricating screw gears. Ensure that the lubrication equipment, such as grease guns or oilers, is clean and free from contaminants. Contaminants, such as dirt or debris, can compromise the lubricant’s performance and increase wear on the gears.

It is important to note that the lubrication requirements may vary based on the specific screw gear system and its operating conditions. Therefore, always refer to the gear manufacturer’s recommendations and guidelines for the most accurate and up-to-date information regarding lubrication requirements.

How do you ensure proper alignment when connecting screw gears?

Ensuring proper alignment when connecting screw gears is crucial for their efficient and reliable operation. Proper alignment helps minimize noise, vibrations, and premature wear, resulting in improved performance and longevity of the gear system. Here’s a detailed explanation of how to ensure proper alignment when connecting screw gears:

- Use Precision Machining: Achieving accurate alignment starts with precision machining of the gear components. The worm gear and worm wheel should be machined to tight tolerances, ensuring proper tooth profile, pitch, and concentricity. High-quality manufacturing processes help ensure the components are dimensionally accurate, which facilitates proper alignment.

- Consider Mounting Configuration: The mounting configuration plays a significant role in aligning screw gears. Whether the gear system is mounted on a shaft or a frame, it is important to carefully follow the manufacturer’s guidelines or engineering specifications for proper mounting. This may involve using specific mounting hardware, such as flanges, couplings, or adapters, to ensure secure and precise alignment.

- Verify Axial Alignment: Axial alignment refers to the alignment of the worm gear and the worm wheel along the gear’s axis of rotation. To verify axial alignment, measurements such as center distance, parallelism, and axial runout should be taken. Precision measuring tools, such as dial indicators or laser alignment systems, can be used to ensure the components are aligned within the specified tolerances.

- Check Radial Alignment: Radial alignment refers to the alignment of the worm gear and the worm wheel in the radial direction. It ensures that the gear meshing occurs at the proper contact point along the gear teeth. Radial alignment can be checked by measuring the radial runout or tooth contact pattern. Adjustments can be made by shimming or using spacers to achieve the desired alignment.

- Consider Preloading: Preloading the screw gear system can help improve alignment and reduce backlash. Preloading involves applying a controlled axial force to the gear components to eliminate any clearance or play between the teeth. This can be achieved through various methods, such as using adjustable bearings or applying a preloaded spring mechanism. Preloading should be done within the manufacturer’s recommendations to avoid excessive loading that could lead to premature wear or damage.

- Follow Manufacturer Guidelines: Manufacturers often provide specific guidelines and recommendations for aligning their screw gear products. These guidelines may include recommended tolerances, alignment procedures, and suggested tools or techniques. It is important to carefully review and follow these guidelines to ensure proper alignment and to maintain any warranty or support provided by the manufacturer.

- Consult with Experts: If you are unsure about the alignment process or encounter challenges in aligning screw gears, it is beneficial to consult with experts or experienced engineers. They can provide guidance, troubleshooting assistance, or even perform precision alignment using specialized equipment or techniques.

By following these practices and taking the necessary alignment measures, you can ensure proper alignment when connecting screw gears. This alignment process helps optimize the performance, efficiency, and service life of the gear system.

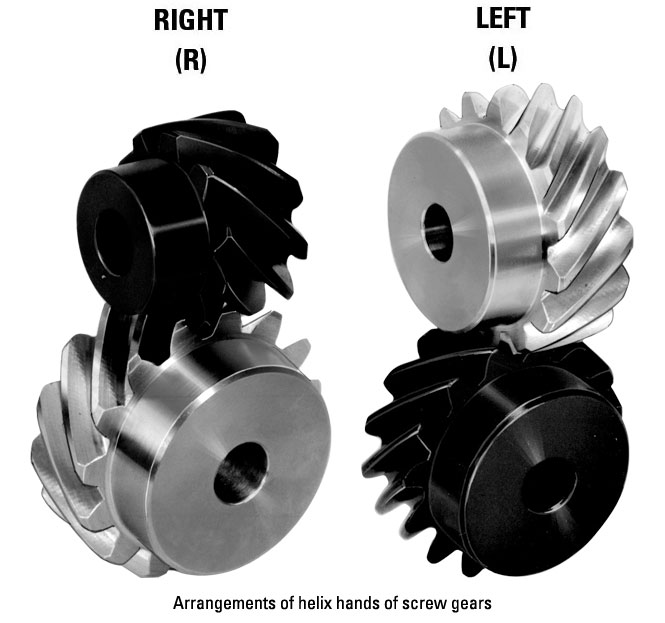

What is a screw gear and how does it work?

A screw gear, also known as a worm gear, is a type of gear mechanism that consists of a screw-like gear (called the worm) and a toothed wheel (called the worm wheel or worm gear). The screw gear operates on the principle of a helical screw driving a toothed wheel to transmit rotational motion and power. Here is a detailed explanation of how a screw gear works:

- Configuration: The screw gear consists of two main components: the worm and the worm wheel. The worm is a cylindrical gear with a helical thread wrapped around it, resembling a screw. The worm wheel is a toothed wheel that meshes with the worm. The orientation of the helical thread on the worm and the teeth on the worm wheel is typically perpendicular to each other.

- Meshing: The worm and the worm wheel mesh together by engaging the helical thread of the worm with the teeth of the worm wheel. The helical thread on the worm acts as a screw, and as the worm rotates, it drives the rotation of the worm wheel. The teeth on the worm wheel provide the necessary contact points for the meshing action.

- Transmitting Motion: When the worm rotates, the helical thread transfers rotational motion to the worm wheel. The helical thread of the worm pushes against the teeth of the worm wheel, causing the worm wheel to rotate. The direction of rotation of the worm wheel depends on the helix angle and the direction of rotation of the worm. The gear ratio between the worm and the worm wheel is determined by the number of teeth on the worm wheel and the pitch of the helical thread on the worm.

- Mechanical Advantage: One of the key characteristics of a screw gear is its ability to provide a high mechanical advantage or gear ratio. The helical design of the worm and the worm wheel allows for a large number of teeth to be engaged at any given time, resulting in a high gear ratio. This makes screw gears suitable for applications that require a significant reduction in rotational speed or an increase in torque.

- Self-Locking: A unique property of screw gears is their self-locking capability. Due to the helical thread design, the friction between the worm and the worm wheel tends to hold the gear system in place when the worm is not rotating. This self-locking characteristic prevents the worm wheel from backdriving the worm. It provides inherent braking or locking action, making screw gears suitable for applications where holding position or preventing reverse rotation is necessary.

- Efficiency and Lubrication: Screw gears generally have lower efficiency compared to other types of gears due to the sliding action between the helical thread and the teeth of the worm wheel. The sliding motion results in higher friction and heat generation. Proper lubrication is essential to minimize wear and improve efficiency. Lubricants with good adhesion and boundary lubrication properties are commonly used for screw gears.

Screw gears are widely used in various applications, including machinery, automotive systems, conveyor systems, lifting equipment, and many others. Their unique characteristics of high gear ratio, self-locking capability, and compact design make them suitable for specific applications where precise motion control, torque multiplication, or holding position is required.

editor by CX 2023-09-11