Product Description

| Product Model | SWL2.5, SWL5, SWL10, SWL15, SWL20, SWL25, SWL35, SWL50, SWL100, SWL120 |

| Product Description | Basic lifting component, compact structure, small size, light weight, no noise, safe and convenient, flexible use, high reliability, wide power source, multiple supporting functions, long service life |

| Usage | Single or combined use, can accurately control the adjustment of lifting or pushing height according to a certain program, can be directly driven by motor or other power, can also be manual |

| Lifting Efficiency and Load Capacity | Special and advanced technology has been developed to improve the overall performance of the jack |

| Structural Type | Type 1 – Screw moves axially; Type 2 – Screw rotates, nut moves axially |

| Assembly Type | Type A – Screw/nut moves upwards; Type B – Screw/nut moves downwards |

| Screw Head Type | Type 1 structure screw head: Type I (cylindrical), Type II (flange), Type III (threaded), Type IV (flat head); Type 2 structure screw head: Type I (cylindrical), Type III (threaded) |

| Transmission Ratio | Ordinary speed ratio (P), slow speed ratio (M), medium speed ratio (F) can be customized according to user requirements |

| Lifting Load Capacity | 2.5kN, 5kN, 10kN, 15kN, 20kN, 25kN, 35kN, 50kN, 100kN, 120kN |

| Screw Protection | Type 1 structure: basic type (no protection), anti-rotation type (F), with protective cover (Z), anti-rotation and protective cover (FZ); Type 2 structure: basic type (no protection) |

Product description: SWL series worm gear screw lift is a basic lifting component with many advantages such as compact structure, small volume, light weight, no noise, safety and convenience, flexible use, high reliability, wide power source, many supporting functions and long service life. It can be used singly or in combination, can adjust the height of lifting or advancing accurately according to certain procedures, and can be driven directly by electric motor or other power, or manually. In order to improve the efficiency and carrying capacity of SWL series worm gear screw lift, special and advanced technology is developed to improve the comprehensive performance of the lift to meet the requirements of the majority of customers. SWL series worm gear screw lift has different structure types and assembly types, and the lifting height can be customized according to the user’s requirements.

RFQ

Q:What information should I tell you to confirm speed reducer?

A: Model/Size, Transmission Ratio, Shaft directions & Order quantity.

Q:What if I don’t know which gear reducer I need?

A:Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q:What should I provide if I want to order NON-STANDERD speed reducers?

A: Drafts, Dimensions, Pictures and samples if possible.

Q:What is the MOQ?

A: It is OK for 1 or small pieces trial order for quality testing.

Q:How long should I wait for the feedback after I send the inquiry?

A: Within 6 hours

Q:What is the payment term?

A:You can pay via T/T(30% in advance+70% before delivery), L/C ,West Union etc

| Standard or Nonstandard: | Nonstandard |

|---|---|

| Application: | Electric Cars, Motorcycle, Marine, Agricultural Machinery, Car |

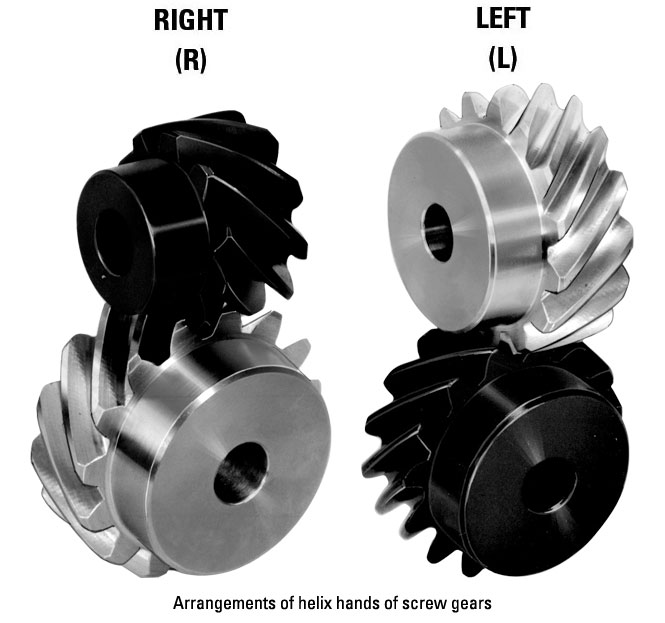

| Spiral Line: | Right-Handed Rotation |

| Head: | Single Head |

| Reference Surface: | Toroidal Surface |

| Type: | ZK Worm |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

What is the purpose of using screw gears in machinery?

Screw gears, also known as worm gears, serve various purposes in machinery and mechanical systems. They offer unique advantages that make them suitable for specific applications. Here’s a detailed explanation of the purposes and benefits of using screw gears:

- High Gear Reduction: One of the primary purposes of using screw gears is to achieve high gear reduction. Screw gears provide a significant reduction ratio, allowing for the conversion of high-speed, low-torque input to low-speed, high-torque output. This makes them ideal for applications that require precise control over torque and rotational speed, such as lifting heavy loads, positioning systems, and machinery with high torque requirements.

- Precise Positioning: Screw gears enable precise positioning and control of linear or rotary motion. The fine-pitch threads on the worm and the corresponding worm wheel teeth allow for accurate and controlled motion. This feature makes screw gears suitable for applications that require precise positioning, such as robotics, automation, and machinery that performs intricate movements or adjustments.

- Self-Locking: Screw gears have a self-locking property, which means that the gear mechanism remains fixed in position even when no external force is applied. The friction between the screw threads and the worm wheel prevents the system from backdriving or rotating unintentionally. This self-locking feature eliminates the need for additional braking mechanisms or external locks, making screw gears advantageous in applications where holding a position is essential for safety and stability.

- Compact Design: Screw gears have a compact design that makes them suitable for applications with limited space. The worm and worm wheel arrangement allows for efficient power transmission in a compact layout, enabling the integration of screw gears in machinery and systems where space is a constraint. This compact design also simplifies installation and reduces the overall footprint of the equipment.

- Quiet and Smooth Operation: Screw gears operate with reduced noise and vibration compared to other gear types. The helical nature of the threads and the sliding/rolling contact between the worm and worm wheel result in a smooth and gradual meshing motion. This smooth operation contributes to quieter machinery, making screw gears desirable in applications where noise reduction is important, such as in residential environments, audio equipment, and precision instruments.

- High Shock Load Resistance: Screw gears are known for their ability to handle shock loads effectively. The helical shape of the threads and the larger contact area between the worm and the worm wheel distribute the load more evenly, reducing the risk of sudden failures or damage due to shock or impact loads. This shock load resistance makes screw gears suitable for applications that involve sudden changes in load or external forces.

- Reliability and Durability: Screw gears are recognized for their reliability and durability. The simplicity of their design, with fewer moving parts, reduces the likelihood of mechanical failures. Additionally, the self-locking feature minimizes the chances of unwanted movement or slippage. When properly lubricated and maintained, screw gears can have a long service life and require minimal maintenance, contributing to the overall reliability of machinery.

- Wide Range of Applications: Screw gears find application in various industries and machinery types. They are utilized in manufacturing equipment, robotics, medical devices, automotive systems, elevators, material handling machinery, and many other systems that require precise control, high torque, compactness, and reliable power transmission.

The purpose of using screw gears in machinery is to provide efficient power transmission, precise positioning, high torque multiplication, self-locking capabilities, and reliable operation. These features make screw gears a valuable component in numerous applications, enhancing performance, safety, and overall functionality of machinery and mechanical systems.

How do you ensure proper alignment when connecting screw gears?

Ensuring proper alignment when connecting screw gears is crucial for their efficient and reliable operation. Proper alignment helps minimize noise, vibrations, and premature wear, resulting in improved performance and longevity of the gear system. Here’s a detailed explanation of how to ensure proper alignment when connecting screw gears:

- Use Precision Machining: Achieving accurate alignment starts with precision machining of the gear components. The worm gear and worm wheel should be machined to tight tolerances, ensuring proper tooth profile, pitch, and concentricity. High-quality manufacturing processes help ensure the components are dimensionally accurate, which facilitates proper alignment.

- Consider Mounting Configuration: The mounting configuration plays a significant role in aligning screw gears. Whether the gear system is mounted on a shaft or a frame, it is important to carefully follow the manufacturer’s guidelines or engineering specifications for proper mounting. This may involve using specific mounting hardware, such as flanges, couplings, or adapters, to ensure secure and precise alignment.

- Verify Axial Alignment: Axial alignment refers to the alignment of the worm gear and the worm wheel along the gear’s axis of rotation. To verify axial alignment, measurements such as center distance, parallelism, and axial runout should be taken. Precision measuring tools, such as dial indicators or laser alignment systems, can be used to ensure the components are aligned within the specified tolerances.

- Check Radial Alignment: Radial alignment refers to the alignment of the worm gear and the worm wheel in the radial direction. It ensures that the gear meshing occurs at the proper contact point along the gear teeth. Radial alignment can be checked by measuring the radial runout or tooth contact pattern. Adjustments can be made by shimming or using spacers to achieve the desired alignment.

- Consider Preloading: Preloading the screw gear system can help improve alignment and reduce backlash. Preloading involves applying a controlled axial force to the gear components to eliminate any clearance or play between the teeth. This can be achieved through various methods, such as using adjustable bearings or applying a preloaded spring mechanism. Preloading should be done within the manufacturer’s recommendations to avoid excessive loading that could lead to premature wear or damage.

- Follow Manufacturer Guidelines: Manufacturers often provide specific guidelines and recommendations for aligning their screw gear products. These guidelines may include recommended tolerances, alignment procedures, and suggested tools or techniques. It is important to carefully review and follow these guidelines to ensure proper alignment and to maintain any warranty or support provided by the manufacturer.

- Consult with Experts: If you are unsure about the alignment process or encounter challenges in aligning screw gears, it is beneficial to consult with experts or experienced engineers. They can provide guidance, troubleshooting assistance, or even perform precision alignment using specialized equipment or techniques.

By following these practices and taking the necessary alignment measures, you can ensure proper alignment when connecting screw gears. This alignment process helps optimize the performance, efficiency, and service life of the gear system.

What industries commonly use screw gears?

Screw gears, also known as worm gears, find applications in a variety of industries due to their unique characteristics and functionalities. The following are some of the industries that commonly use screw gears:

- Manufacturing and Machinery: The manufacturing and machinery industry extensively utilizes screw gears in various equipment and machinery. Screw gears are commonly found in gearboxes and power transmission systems, providing speed reduction and torque multiplication. They are used in conveyor systems, packaging machines, material handling equipment, and other industrial machinery that require controlled motion and high gear ratios.

- Automotive: The automotive industry utilizes screw gears in specific applications, most notably in steering mechanisms. Screw gears are employed in worm and sector steering gears to convert the rotational motion of the steering wheel into the linear motion required for turning the vehicle’s wheels. The self-locking property of screw gears is advantageous in maintaining the position of the wheels after steering input.

- Elevators and Lifts: Screw gears are widely used in the elevator and lift industry for vertical transportation systems. They play a crucial role in the elevator hoisting mechanism, where the rotational motion of the motor is converted into vertical movement. The high gear reduction ratio provided by screw gears enables controlled and precise lifting operations in elevators and lifts.

- Valve and Actuation Systems: Screw gears have significant applications in industries that involve valve control and actuation. They are utilized in valve actuators to convert rotational motion into linear motion for precise positioning of valve stems. Screw gears are commonly found in water treatment plants, oil refineries, chemical processing facilities, and other industries that require accurate flow control and fluid system management.

- Robotics and Automation: Screw gears play a vital role in robotics and automation systems. They are utilized in robot joints and robotic arm mechanisms to provide precise movement and positioning. Screw gears enable controlled and repeatable motion, making them suitable for applications that require accurate manipulation, such as assembly lines, pick-and-place machines, and robotic surgery systems.

- Camera and Optics: The camera and optics industry utilizes screw gears in lens control systems. Screw gears are employed for focus adjustment, zooming, and aperture control in camera lenses and telescope mechanisms. The precise movement provided by screw gears enables accurate focusing, zooming, and optical alignment, contributing to high-quality image capture and optical performance.

- Medical Equipment: Screw gears find applications in the medical equipment industry, particularly in devices that require controlled and precise movement. They are used in surgical robots, prosthetic limbs, medical imaging devices, and other medical instruments. Screw gears enable accurate motion control and positioning, while their self-locking property is advantageous for maintaining stable positions and preventing undesired movement.

- Security Systems: Screw gears are utilized in security systems, including combination locks and safes. They provide the mechanical advantage necessary for rotating the locking mechanisms and ensuring secure operation. The self-locking property of screw gears adds an extra layer of security by preventing unauthorized access through reverse rotation or manipulation.

These are just a few examples of the industries that commonly use screw gears. The unique capabilities of screw gears, such as high gear ratios, precise motion control, and self-locking functionality, make them valuable in various sectors where efficient power transmission, accurate positioning, and controlled movement are essential.

editor by CX 2023-09-07